One debate you see play out on forums across the internet is how to upgrade your brakes without breaking the bank. As multi-piston brakes become ever more affordable and widely available with cost-effective overseas  manufacturing processes, they are popping up all over the place. We see many similar designs with different logos painted on them. However, there are reasons why a big brake setup might not be for you and your ride.

manufacturing processes, they are popping up all over the place. We see many similar designs with different logos painted on them. However, there are reasons why a big brake setup might not be for you and your ride.

There is such a thing as too much brake! Many big brake kits are far more than most cars need and increase rotational weight. Your car has to work harder to turn that weight and lug around unsprung mass. If you don’t have big horsepower and loads of torque, it might be time to look at minimal upgrades for rotors, pads lines and fluids.

The trend to go minimalist with a braking system has distinct advantages. Using OEM calipers and the original spec rotor dimensions is less intrusive and does not require massive wheels to accommodate them. They require no modification of the dust shield or any replacement of brake lines. When you look at the physics, your car will have the same acceleration out of the hole because your motor doesn’t use more torque to spin up big and heavy rotors. The rule is one pound of rotating mass is equal to eight pounds of dead weight, so every pound in any rotating assembly is critical.

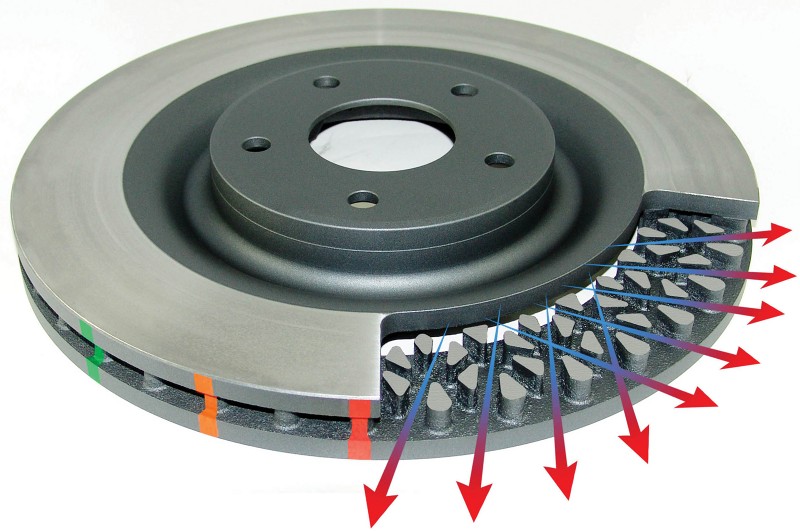

Disc Brakes Australia (DBA) has the market covered when it comes to rotors. They have applications for everything made in North America and even stuff that was never sold here but imported from Japan. DBA has been around for decades and their patented technology for dissipating heat is called the Kangaroo Paw. Taking a look at the cut away section, it shows how the unique vented rotors shed heat versus the standard design vanes every one else uses. The braking surface is also slotted to prevent gas and heat buildup and dissipates it rapidly. We prefer the slotted surface over cross-drilling as small stress cracks can form around the holes, as we’ve learned first hand.

DBA also features more patented technology with their color temperature indicator strips located on the rotor itself. Dubbed the Thermo-Graphic Temperature Monitor, it will change color if the rotor exceeds a certain temperature, and can indicate how the brakes are performing during your next track day.

Initial Color Exceeded Temperature Result Color

GREEN 458°C WHITE

ORANGE 550°C YELLOW

RED 630°C WHITE

By observing the temperature strips, you can run that extra cool down lap in the pits or on the track to ensure you’re not warping your new DBA rotors. However, they are made from high tensile steel which is heat treated and maintains maximum thickness to combat this undesirable condition. With a proper cool down after spirited drives or track days, DBA is confident your rotors will perform for many years of improved braking. DBA has various lines for improved braking depending on the application.

Street Series: Normal Street Driving

4000 Series: Street Driving and Motorsports

5000 Series: 2-Piece Rotors for Extreme Street and Track Driving

When installing new rotors, DBA highly recommends changing the pads at the same time. When selecting a pad, you want to find one that suits your needs. For your everyday drive, low dust and low noise are a consideration.  On the other hand, for an all-out track day, it is resistance to heat and fade-free braking with those other factors not a concern. DBA recommends Hawk Performance pads for their brakes to ensure the best possible combination.

On the other hand, for an all-out track day, it is resistance to heat and fade-free braking with those other factors not a concern. DBA recommends Hawk Performance pads for their brakes to ensure the best possible combination.

BEDDING-IN

Before we install the DBA rotors, we ensured that they were cleaned thoroughly after hitting them with some brake cleaner. This will rid the surface of any oils and grease or any debris that will affect your braking. After everything is assembled, it is time for the proper bedding-in process with the new pads.

Take the car up to 100km/h (65mph) and jam the brakes just to the point of engaging ABS all the way down to 25km/h (15mph). It should be a hard stop and it will improve as you heat up the pads by repeating 8-10 times. Try to leave no long gaps in between the hard stops and do not come to full stop as this will imprint the pad on the rotor and cause vibration. At the end of the cycle, there may be a noticeable bit of fade but this is normal as the system beds-in. After these solid stops, let the car sit for a 15 minute brake-free drive to cool everything down. After these stops, the DBA rotors will turn a healthy, bluish gunmetal color. They are now ready for the street/track but suggest we the optimal performance will occur after about 500km (300mi).

SOURCE:

Disc Brakes Australia

Street, 4000-Series & 5000-Series Rotors

www.dba.com.au

Related Articles

Wilwood Announces Wilwood Corvette Challenge + Speed Ventures Partnership 2024

Wilwood Announces Wilwood Corvette Challenge + Speed Ventures Partnership 2024

Unboxed: R1 Concepts Brake Kits - Performance & OEM Replacement

Unboxed: R1 Concepts Brake Kits - Performance & OEM Replacement

Wilwood Superlite Front BBK for BMW E36 M3

Wilwood Superlite Front BBK for BMW E36 M3

Ford and xix3D Unveil the Ford Wrap Program: A New Horizon in Vehicle Customization

Ford and xix3D Unveil the Ford Wrap Program: A New Horizon in Vehicle Customization

Project Mu XC6 Caliper kit for 6H Truck and SUV

Project Mu XC6 Caliper kit for 6H Truck and SUV

Project Mu Rear Forged Sport Calipers w/ Side Brake

Project Mu Rear Forged Sport Calipers w/ Side Brake