One of the current rages in the turbocharger aftermarket is the billet compressor wheel. The traditional compressor wheel for most turbochargers is made of cast aluminum. Cast aluminum is a reasonably good material to make a complex part such as a compressor wheel out of economically in large scale production. However, cast aluminum is not as strong and does not have as good mechanical properties as billet aluminum.

One of the problems cast wheels can have are small voids and other internal defects. These voids can cause points of stress concentration inside the compressor wheel which carries a lot of load due to the high rpm it turns at (up to and over 150,000 rpm in some cases). These areas of high stress are called stress risers and can result in wheel failure. The other issue is that the mechanical properties of cast aluminum are limited as far as strength. For these reasons a cast wheel has to be designed with these issues in mind and the blades are made thicker and the center hub chunkier and stronger.

|

|

Finish the article at motoiq.com

Related Articles

PASMAG Editors’ Top 5 SEMA Builds of 2025

PASMAG Editors’ Top 5 SEMA Builds of 2025

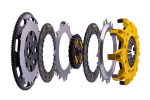

ACT Releases SFI-Approved 225mm Mod-Twin for 1989-1992 Nissan Skyline GT-R (R32)

ACT Releases SFI-Approved 225mm Mod-Twin for 1989-1992 Nissan Skyline GT-R (R32)

MID Wheels by RAYS Introduces the All-New D8 Off-Road Wheel

MID Wheels by RAYS Introduces the All-New D8 Off-Road Wheel

Unitronic TCU Tuning for the 8Y Audi RS3

Unitronic TCU Tuning for the 8Y Audi RS3

Chopping Block: Acura RDX

Chopping Block: Acura RDX

First BMW M EV confirmed for 2027

First BMW M EV confirmed for 2027